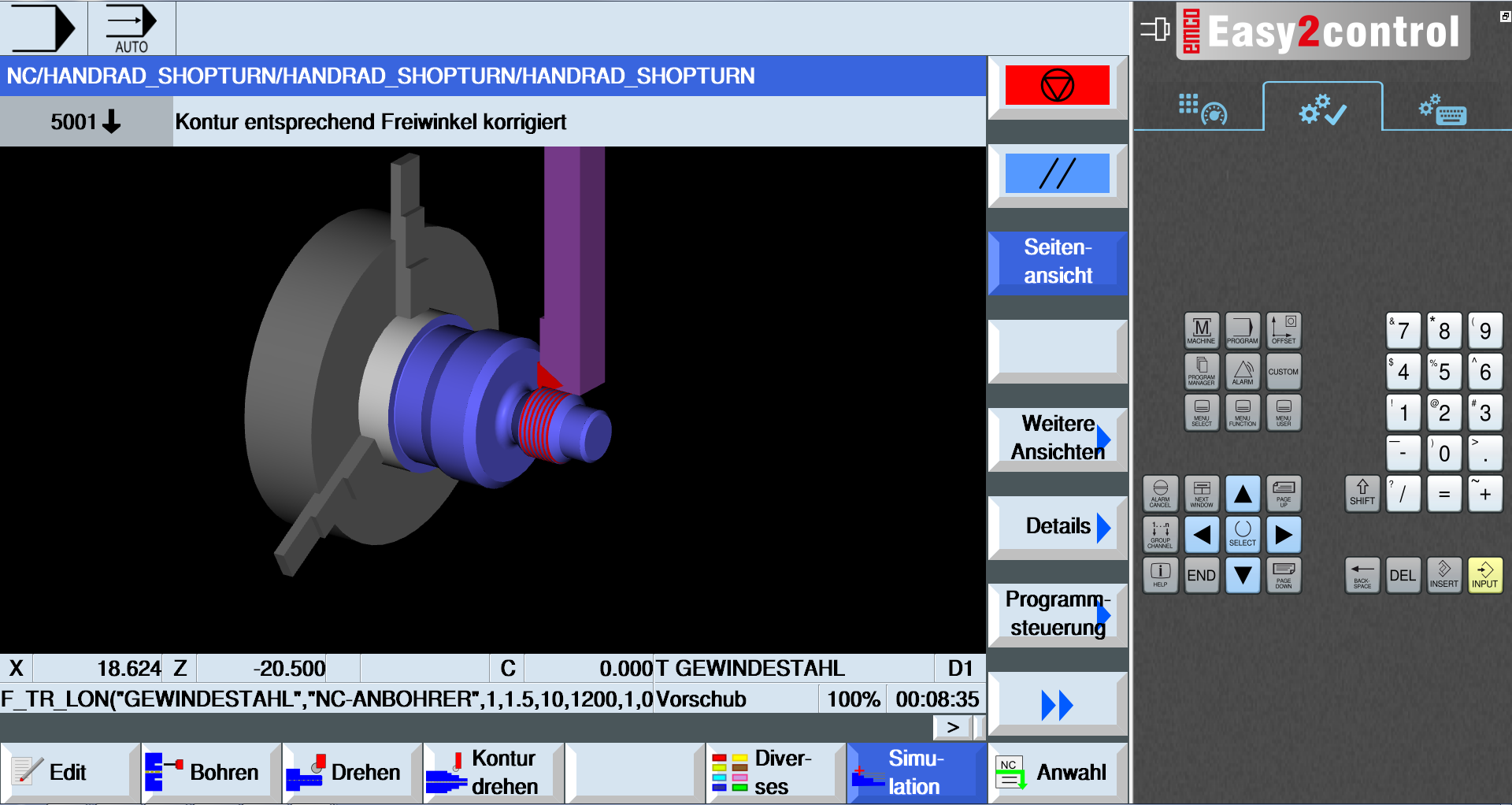

Win3D-View

Win3D-View is a 3D simulation for turning and milling and is available as an option in addition to the WinNC Control.

Graphic simulations of CNC controls are designed especially for industrial experience.

Win3D-View displays exceed industry standards.

Tools, blanks, clamping devices, and work processes are highly realistic.

The system checks the programmed travel of the tool to prevent collision with clamping devices and blanks.

If there is a conflict, a warning is given so that manufacturing processes can be understood and controlled from the very beginning.

That's the aim of Win3D-View: Visualizing, supporting and avoiding costly collisions.

Highlights

Functions

Collision control

The programmed travels of the tool are tested for collisions (even with motion speed or with standing spindle) with clamping devices or with the raw part by the system. In case of danger an alarm is set.

Realistic construction

The entire work area incl. chuck, tailstock and vice as well as tools, raw parts, clamping devices and the machining process are displayed highly realistic.

Integrated tool library

Tools that are suitable for the machining of workpieces can be looked up and selected in the tool library.

Licenses

Homeschooling license

Extension of the multiple license. Any number of distance students can also install the programming stations off-site. The license is valid for 5 years and thus covers more than one teaching cycle.

Multiple license

For external NC programming of NC controlled machine tools. It may be installed within an institute registered by the licenser in an unlimited number on PC workstations respectively in a network.

Downloads

Software-Demos

Software demo / full version / homeschooling

Just give our WinNC software a try or get up to date!

All WinNC controls can be tested as demo versions free of charge and without obligation.

If you already have a WinNC software activated by a valid license key, you can bring it up to date with an update installation.

Please ensure that, in case of an update, all WinNC-components (WinNC-controls, 3DView, DNC, Robotic, CAMConcet,..) located in the regarding Directory must be updated to the current release-version.

Our DEMO versions contain the full range of functionality (only programming stations, direct control of machines is only possible via licensed software), but their useful life is limited to 30 days (from the date of installation).

By entering a valid license key all demo versions can easily by converted into a full version or a homeschooling version at any time

| Title | Version | Filesize | |

|---|---|---|---|

| 3D-View for WinNC | 1.50.0002 | 53 MB | -1 |

| Title | Version | Filesize | |

|---|---|---|---|

| MSD/PLC | 2025.01.07 | 748 KB | -1 |

| short description für update installation | A2014-09 | 415 KB | -1 |

| Kurzanleitung für Update | A2014-09 | 405 KB | 0 |

Versionhistory

| Version | Date | Changes | ||

|---|---|---|---|---|

| 14.50 | 07.012.2022 | Compatibility WinNC/td> | ||

| 14.48 | 23.02.2021 | Compatibility measurement cycles | ||

| 14.46 | 02.04.2020 | Support for swiveling table | ||

| 14.44 | 23.01.2019 | Support 4th axis at WinNC for Sinumerik Operate and Heidenhain TNC 640 | ||

| 14.42 | 30.05.2017 | Compatibility WinNC for Heidenhain TNC 640 | ||

| 14.09.2015 | Release for Windows 10 | |||

| 14.40 | 19.12.2014 | Enhencements for 'WinNC for Fanuc31i' | ||

| 14.38 | 23.05.2014 | Minor corrections | ||

| 14.36 | 11.03.2013 | Compatibility Windows 8 | ||

| 14.34 | 15.05.2012 | Compatibility 'WinNC for Sinumerik Operate' | ||

| 14.32 | 25.09.2009 | Integration CM250 | ||

| 14.30 | 19.05.2009 | Enhancements for EASY CYCLE | ||

| 14.28 | 02.12.2008 | Problem with empty tooltable at 3dView-start solved | ||

| 14.26 | 23.06.2008 | Integration CM450 | ||

| 14.22 | 30.10.2007 | Simulation can be continued after collision-detection | ||

| 14.20 | 19.04.2007 | Improvements Tooldata | ||

| 14.18 | 04.04.2007 | Improvements clamping device | ||

| 14.16 | 19.03.2007 | VISTA, UNICODE, machine vises | ||

| 14.10 | 22.02.2006 | Improved representation of the clamping device for milling-machines | ||

| 14.08 | 01.12.2005 | Improvement of taping | ||

| 14.06 | 14.06.2005 | Enhancements for taping | ||

| 14.04 | 03.06.2005 | Tool-Generator | ||

| 14.00 | 05.05.2004 | Transmit, Tracyl and 4th axis |

Instructions/Manuals

Here you will find all information and instructions for the installation and use of the 3D-View for the WinNC controllers

- WinNC for FAGOR 8055

- WinNC for HEIDENHAIN TNC 426

- WinNC for FANUC 0/21

- WinNC for SINUMERIK 810/820

- WinNC for SINUMERIK 810D/840D

For all newer WinNC controllers, the documentation is integrated into the corresponding control descriptions.

| Title | Version | Filesize | |

|---|---|---|---|

| 3DView-Dokumentation Fräsen | C2007-02 | 1 MB | 0 |

| 3DView manual milling (czech) | C2014-06 | 1 MB | 7 |

| 3DView manual turning (dutch) | C2007-02 | 504 KB | 3 |

| 3DView manual turning (italian) | B2006-02 | 496 KB | 6 |

| 3DView manual turning (spanish) | C2007-02 | 1 MB | 5 |

| 3DView manual turning (french) | C2007-02 | 1 MB | 2 |

| 3DView manual turning | C2007-02 | 1,012 KB | 1 |

| 3DView-Dokumentation Drehen | C2007-02 | 976 KB | 0 |

| 3DView manual milling (dutch) | C2007-02 | 739 KB | 3 |

| 3DView manual milling (italian) | B2006-02 | 669 KB | 6 |

| 3DView manual milling (spanish) | C2007-02 | 2 MB | 5 |

| 3DView manual milling (french) | C2007-02 | 1 MB | 2 |

| 3DView manual milling | C2007-02 | 1 MB | 1 |

| 3DView manual turning (czech) | C2013-09 | 1 MB | 7 |

Options/Accessories

Concept machines

Whether for small businesses or for professional CNC training the Concept machines can be applied flexibly. With its modular concept the machine series can be used in a productional CIM network as well as for training purposes equipped with training softwares and coursewares.

For more information about the Concept machines click "machines" in the main menu.