Universal Machining Centre Ecomill

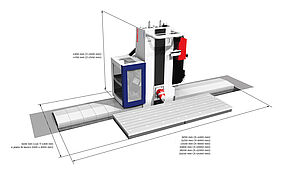

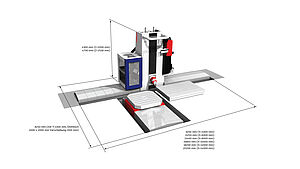

Universal Machining Centre with horizontal spindle and moving column

EQUIPMENT

Technical data

Work area

| Travel in X/Y/Z | X-axis: 4000 - 14000 mm, Y-axis: 1300 mm, Z-axis: 2500 mm |

| Number of axes (basic machine) | 3+2 |

| Rapid motion speeds in X/Y/Z | 30 m/min |

| Max. table load | Max. table load on floor plate: 15000 kg/m² |

Tool change

| Number of tool stations | 40/60/80 Plätze |

Milling spindle

| Number of tools | 40 |

Highlights

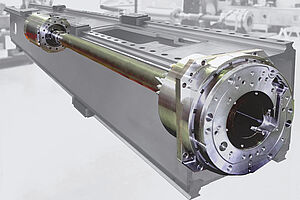

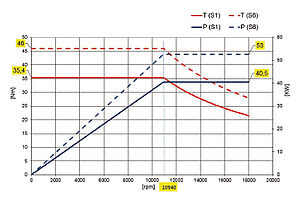

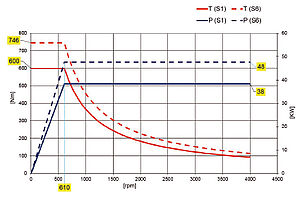

DIRECT DRIVE SPINDLE

Direct drive transmission ensures high reliability and long-life of the machine spindle line.RAM

The generous ram cross-sections of 520 mm x 450 mm for the ECOMILL and 585 mm x 500 mm for the ECOMILL PLUS mean high moments of resistance against deflection, which in combination with the four guides of the box-in-box system guarantee maximum rigidity and precision.Overall dimensions/Work space

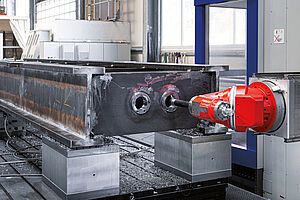

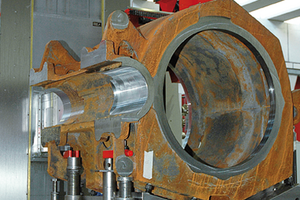

Application Cases

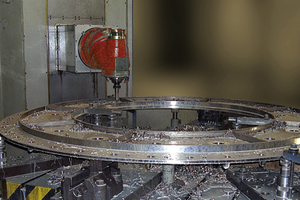

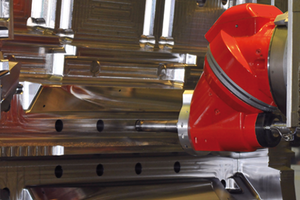

mould & die

aerospace

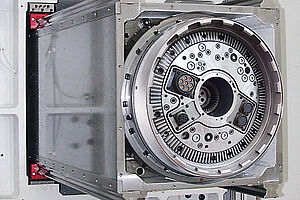

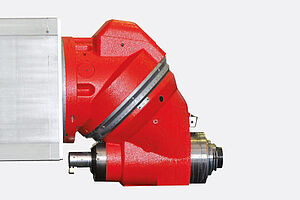

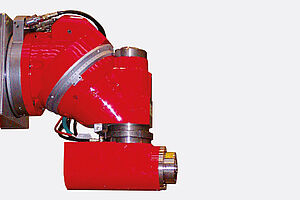

Milling heads

Universal milling head with automatic millesimal positioning

General engineering - energy - automotive - aerospace - railway - earthmoving - naval - construction machinery and agricultureOptions/Accessories

DREHTISCHE

Dreh- oder Drehverschiebetische können in jeder Plattengröße und Tragfähigkeit installiert werden, auch in Kombination mit Pendelbetrieb.LASER

Das Laser-Werkzeugeinstellsystem befindet sich oben auf dem Maschinenständer und ist gegen Schmutz und mögliche Stöße geschützt.WERKZEUGWECHSEL

Kettenwerkzeugmagazin von 40 bis 120 Werkzeugen, Turmwerkzeugmagazin bis zu 203 Werkzeugen verfügbar.Software/Control

Sinumerik ONE with Operate

The Sinumerik ONE is the universal and flexible CNC system. With a wide range of functionality, it is suitable for use in almost all technologies. The Sinumerik ONE sets standards in terms of dynamics, precision and integrability in networks.

With the Sinumerik ONE you rely on:

- highest performance and flexibility

- universal openness

- highly effective personal and machine protection

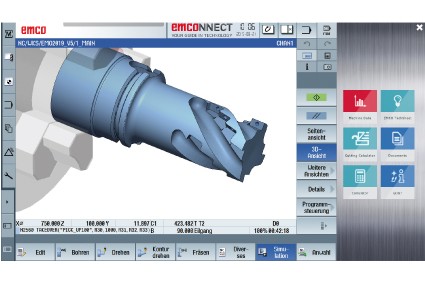

Sinumerik & EMCONNECT, the digital process assistant

EMCONNECT is included in the standard machine. Switching between emcoNNECT apps and the control system is possible with a single click. All production-relevant data can be displayed in full-screen or sidebar view.

The new SINUMERIK ONE has been specially developed for smart manufacturing.

- Digital twin is an integral part of the CNC control, virtual and real control merge and complement each other

- Significant reduction in product development and time-to-market thanks to the digital first strategy

- Improved networking and data communication capabilities

- Significant reduction in the duration of real commissioning through virtual preparation for commissioning

- Significantly increased CNC performance

- Significantly shorter non-productive times and complete integration into the TIA Portal through the integrated SIMATIC S7-1500F PLC

This means that the SINUMERIK ONE can be seamlessly integrated into digital solutions and workflows.

![[Translate to en:] [Translate to en:]](/fileadmin/user_upload/_Group/pics_products/Steuerungen/Heidenhain/pic_425x283_Steuerung_Heidenhain_TNC_7.jpg)

Heidenhain TNC 7

With the new TNC7 control from HEIDENHAIN, users and machine tool builders experience completely new possibilities in the programming and operation of their machines.

Because operation is intuitive, task-oriented and customised, making work in the workshop faster, safer and more pleasant.

Highlights of the Heidenhain TNC 7:

- 24 control loops, 4 of which are spindles

- Very high operating dynamics and fluid, intuitive multi-touch operation

- Milling and turning operations

- Intuitive set-up of workpieces with smart probing functions

- Graphically supported alignment of clamping devices

- Short block processing time (0.5 ms)

- High-end performance for perfect surfaces and highest accuracy

- Integrated process monitoring