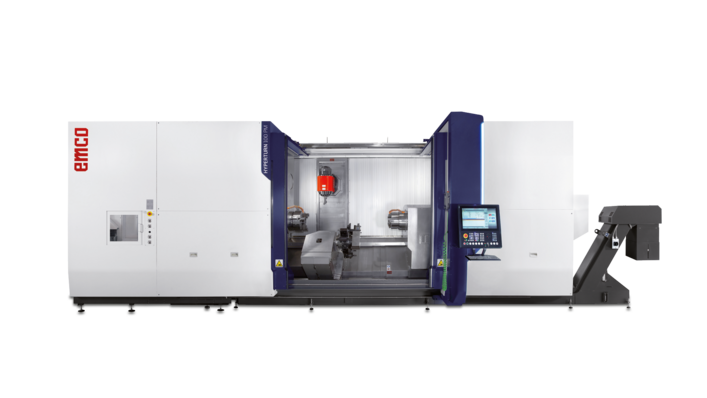

Hyperturn 100 Powermill

EQUIPMENT

Technical data

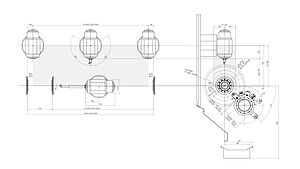

Work area

| Travel in X/Y/Z | 780 (+760/-20) // 420 // 1500 / 2200 / 3100mm |

| Max. turning diameter | 720 mm (with Milling spindle) |

| Swing over bed | 800 mm |

| Rapid motion speeds in X/Y/Z | 30 / 40 / 20 m/min |

| Feed force in X/Y/Z | 1640 / 1640 / 1640 N |

Main spindle

| Max. speed | 3500 // 2500 rpm |

| Spindle nose | A2-8" // A2-11" |

| Max. drive power | 33 / 53 kW |

| Max. torque | 800 // 4400 Nm |

Tool change

| Number of tool stations | 40 / 100 |

| Max. tool diameter | 90 mm |

General data

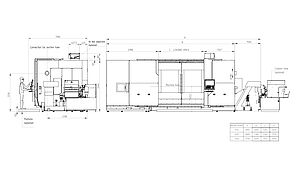

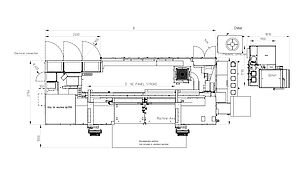

| Dimensions (LxWxH) | 8100 / 8800 / 9600 x 3200 x 3000 mm |

| Machine weight | 25000 – 35000 kg |

Highlights

Work Area

The spacious work area has been designed for workpieces featuring a turning diameter of up to 750 mm. The complete machining of complex workpieces in one setup is possible when using an NC steady rest and a counter-spindle.

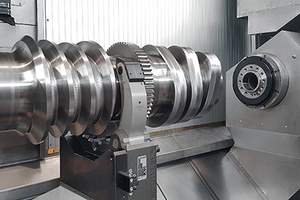

Main spindle and counter-spindle (A2-11")

Featuring performance data that enable all types of machining without any compromises. The Emco spindle concept comes with two servomotors that also act as a C-axis. The motors work synchronously, guarantee the compensation of plays and enable the achievement of the outputs and torques shown in the diagram. What is more, the main spindle and the counter-spindle are equipped with a special EMCO cooling system that optimises the temperature stability and guarantees maximum precision regardless of the machining duration.

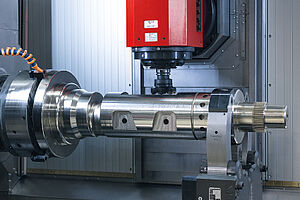

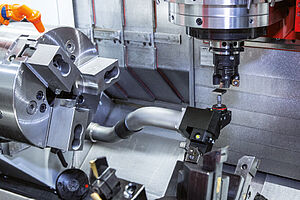

Milling spindle

The standard version comes with 12000 rpm and is suitable for all turning, drilling and milling operations and technologies. The water-cooled ISM (integrated spindle motor) can be delivered with up to 33,8 kW and a maximum torque of 165 Nm as well as with HSK-T 63 or PSC63 (Capto C6). Coolant inside and outside (up to 80 bar), which allows for the efficient production of turned and milled parts.

Maintenance Center

The maintenance center is located at the rear left of the machine. The pneumatic unit is located here. Clamping pressures can now be programmed and defined in the part program.

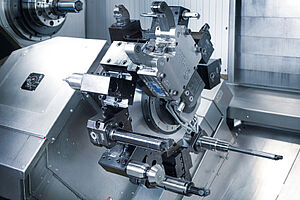

Tool Turret

Tool disk is integrated. The tools are driven directly. Without gear train. Without gear wheels. Without vibrations and almost noiseless.

Overall dimensions/Work space

Options/Accessories

Tool Measuring

The tool probe in the workspace enables fast and precise measurement of the tools both in the milling spindle and on the turret in the workspace.

Touch Probe

Measuring probe with various receptacles for automatic measurement of workpieces in the working area with subsequent tool correction. With measuring set for checking and correcting the kinematic accuracy of 5-axis machining.

CNC steady rest

Different hydraulic steady rests are available for shaft machining. Small shaft parts can be supported with a turret steady rest up to 180mm. For large shaft parts, a CNC steady rest with centering ranges up to 520 mm is available.

Software/Control

Sinumerik ONE with Operate

The Sinumerik ONE is the universal and flexible CNC system. With a wide range of functionality, it is suitable for use in almost all technologies. The Sinumerik ONE sets standards in terms of dynamics, precision and integrability in networks.

With the Sinumerik ONE you rely on:

- highest performance and flexibility

- universal openness

- highly effective personal and machine protection

Sinumerik & EMCONNECT, the digital process assistant

EMCONNECT is included in the standard machine. Switching between emcoNNECT apps and the control system is possible with a single click. All production-relevant data can be displayed in full-screen or sidebar view.

The new SINUMERIK ONE has been specially developed for smart manufacturing.

- Digital twin is an integral part of the CNC control, virtual and real control merge and complement each other

- Significant reduction in product development and time-to-market thanks to the digital first strategy

- Improved networking and data communication capabilities

- Significant reduction in the duration of real commissioning through virtual preparation for commissioning

- Significantly increased CNC performance

- Significantly shorter non-productive times and complete integration into the TIA Portal through the integrated SIMATIC S7-1500F PLC

This means that the SINUMERIK ONE can be seamlessly integrated into digital solutions and workflows.

EMCONNECT - Digital Process Assistant

For increased productivity and efficiency in production.

EMCONNECT facilitates easy access to digital production – all important information and systems are accessed centrally on the machine. The familiar NC control and hence the familiar operation of the machine remain unchanged.

A clear and compact overview of the machine state, the machine data and the operating mode is available at a glance thanks to the emcoNNECT Dashboard. The hardware basis of the EMCONNECT control centre is a 22“ multi-touch display teamed with an industrial PC and a keyboard including HMI hotkeys for easy and intuitive operation via a user interface optimised for touchscreen use.

Included as standard equipment in the Siemens machine version (Sinumerik ONE).

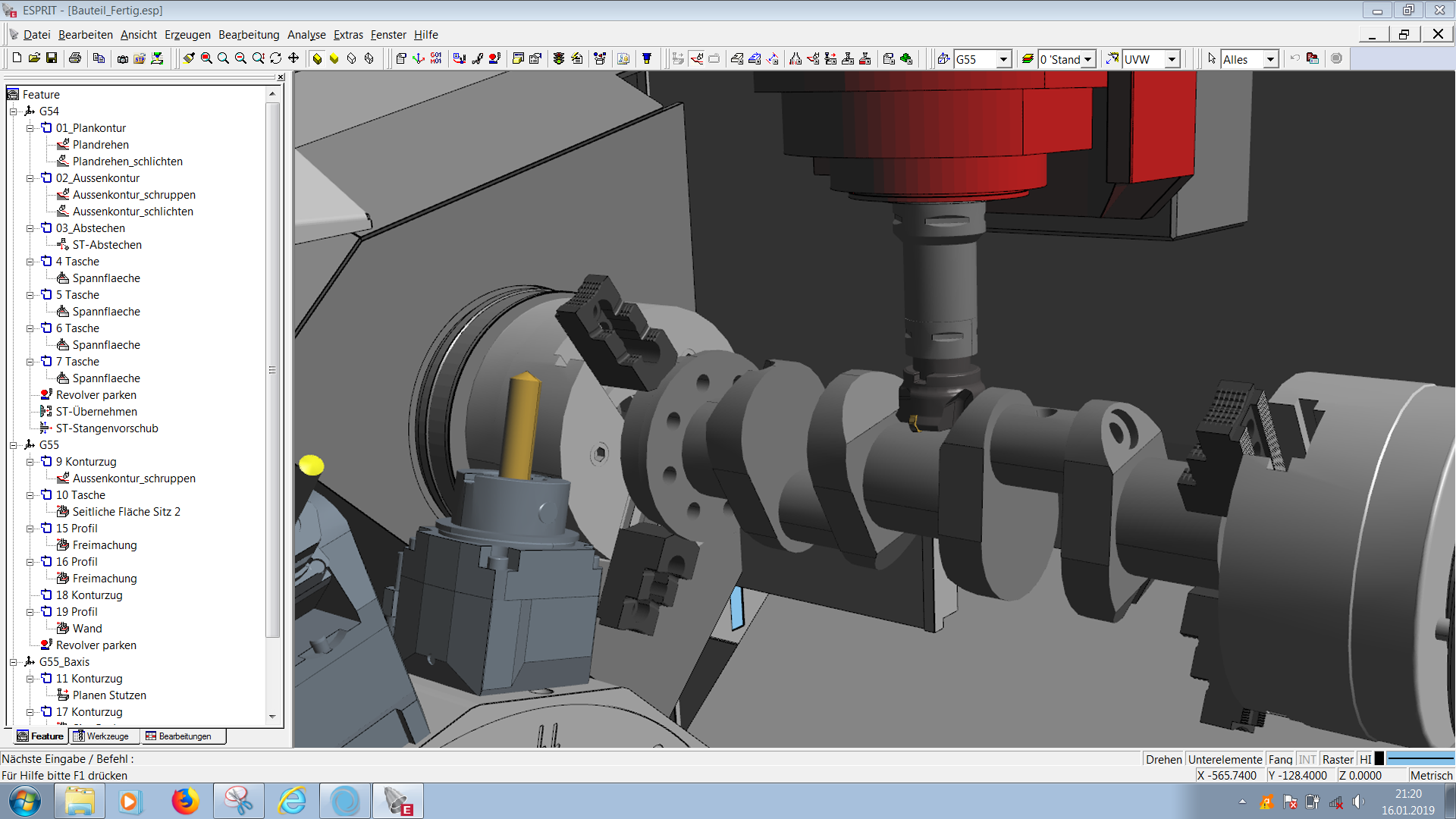

Esprit (optional)

The sensational CAM solution for turning and turning/milling. ESPRIT greatly simplifies the programming of complex machining processes and significantly reduces set-up times.

- Complete CNC programming for up to 22-axis turning

- Turning/milling for single-spindle lathes

- Turning/milling for multi-carriage turning centers

- Turning/milling for multi-tasking machine tools including B axis

Simulations:

- Dry runs in dynamic volume view

- Shaded in the entire working environment: Machine tool, clamping devices, blank and workpiece

- Extensive collision detection: Tool, blank, workpiece clamping devices and target/actual workpiece comparison

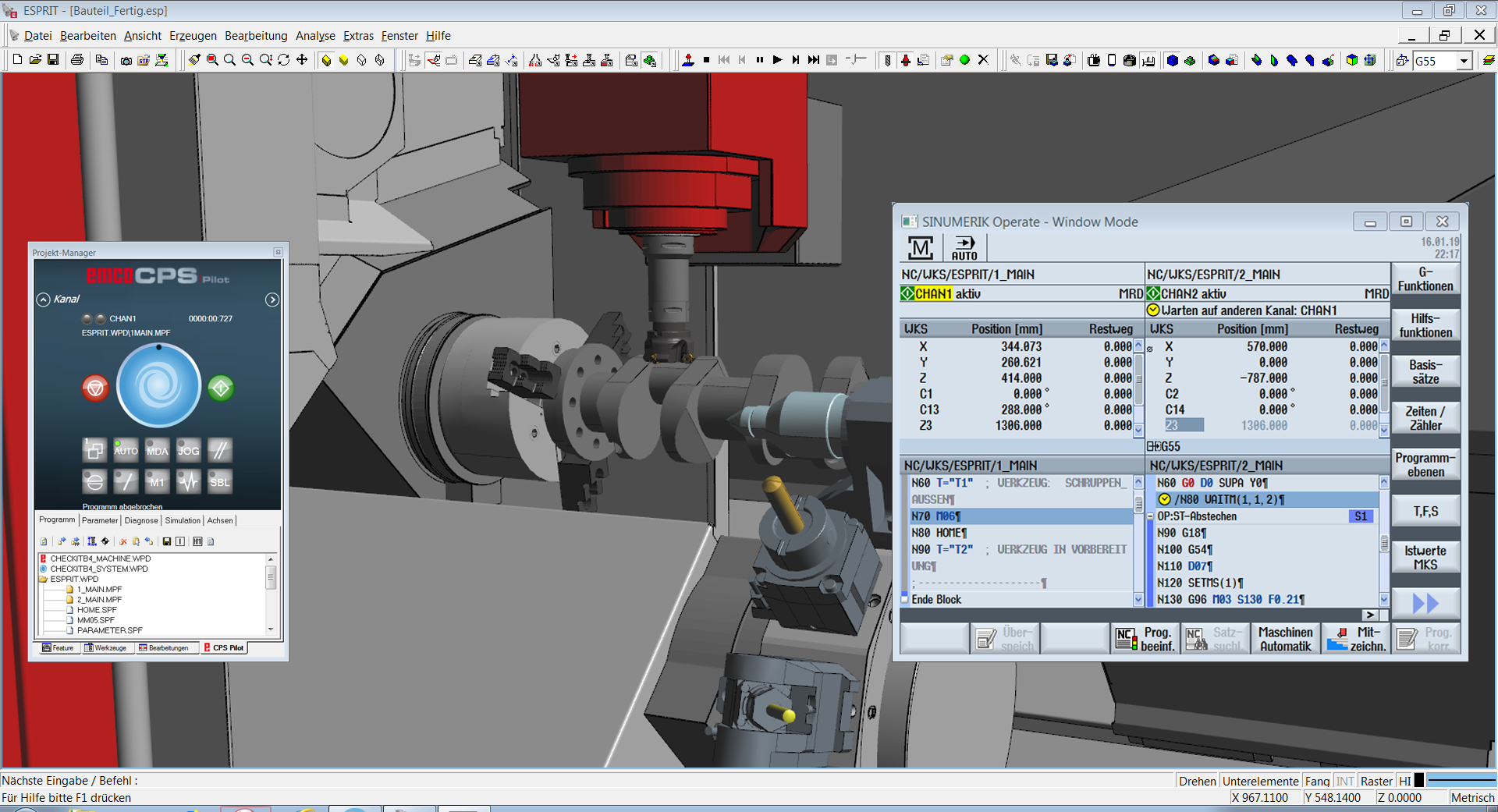

EMCO CPS Pilot (optional)

EMCO CPS PILOT is the virtual EMCO machine on the PC. The operator works at an external programming station with an image of the machine in simulated operation. Therefore, NC programs can be planned, programmed, simulated and honed.

Using CPS the result is 100 % production reliability, up to 80 % shorter set-up times and an enormous increase in productivity and operating efficiency.

- 100 % identical behavior of machine and PC

- Collision monitoring for clamps, parts, tools, tool holders and machine components

- Collisions can be completely eliminated before they even happen

- The machine's productivity is maximized

- Perfect tuning of both tooling systems

- Resimulation and optimization of existing NC programs

- Fewer rejects

- Ideal for internal machining and operator training courses (no machine downtimes!)

- Very little training required, as identical with the machine's user interface