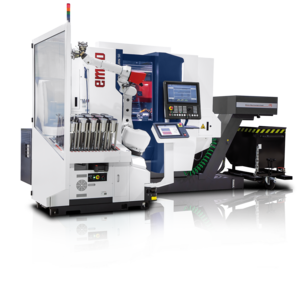

Emcoturn E45

Technical data

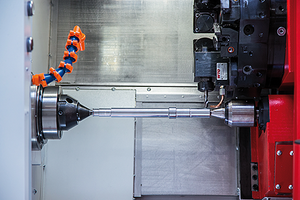

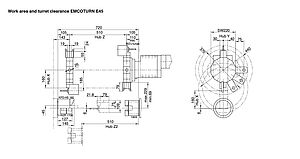

Work area

| Travel in X/Y/Z | 160//+40/-30 / 510 mm |

| Bar diameter | 45 (51) mm |

| Max. turning diameter | 220/300 mm |

| Swing over bed | 430 mm |

| Distance between centers | 670 mm |

| Rapid motion speeds in X/Y/Z | 24/10/30 m/min |

Main spindle

| Max. speed | 6300 (5000) rpm |

| Spindle nose | A2-5 |

| Max. drive power | 13 kW |

| Max. torque | 78 (100) Nm |

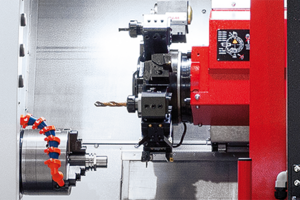

Counter spindle

| Max. speed | 6300 rpm |

| Spindle nose | A2-4 |

| Max. drive power | 10/7,5 kW |

| Max. torque | 42/43 Nm |

Tailstock

| Inner cone | MK4 |

| Travel (automatic) | 510 mm |

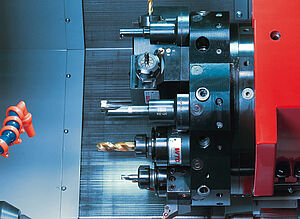

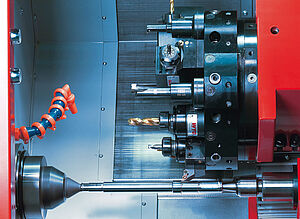

Tool turret

| VDI size | 25/30 |

| Number of tools | 12 |

| Driven tools | 6 |

| Max. speed | 5000 rpm |

| Max. drive power | 4 kW |

| Max. torque | 16 Nm |

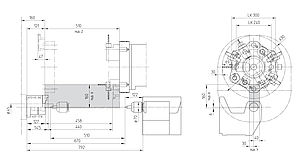

General data

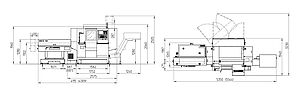

| Dimensions (LxWxH) | 2575 x 1760 x 1960 mm |

| Machine weight | 4000 kg |

Highlights

Overall dimensions/Work space

Workpieces

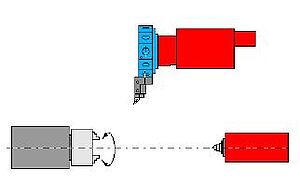

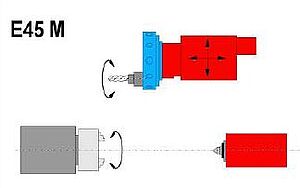

Examples of use

Versions

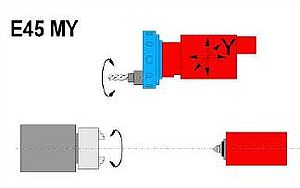

Emcoturn E45 MY - SIEMENS / FANUC / HEIDENHAIN

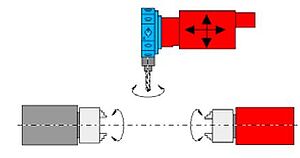

incl. driven tools, C-axis, Y-axis and tailstock.Emcoturn E45 SM - SIEMENS / FANUC / HEIDENHAIN

incl. counter spindle, driven tools and C-axis.Emcoturn E45 SMY - SIEMENS / FANUC / HEIDENHAIN

incl. counter spindle, driven tools, C-axis and Y-axis.Options/Accessories

Chip conveyer

Chain feeding system with a dump-height of 1200 mm, suitable for: long steel shavings, snarl and wool chips for dry and wet machining.Band filter with high-pressure coolant pumps

A coolant pressure of 25/40/60 or 80 bar can be set as needed. This enables coolant-fed drilling and milling tools to be used to their best advantage.Automation

Turn / Mill Assist

Compact standard automation for small and medium-sized batches for turning and milling machines.

- Reduction of working hours by up to 70%

- Compact and space-saving solution

- Graphically supported operation

- Free access to the machine door

- For small and medium-sized series

- Very short configuration and setup times

- No special knowledge about robots required

- On-site installation and training

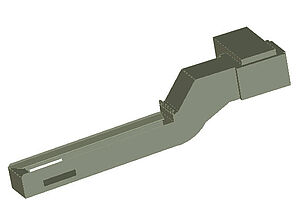

Short-bar loader EMCO SL 1200

The EMCO short-bar loader SL 1200 is the perfect solution for the automatic reloading of pre-cut bars up to 1200 mm.

The adavantage: small footprint and short loading times through shorter strokes.

The control unit is perfectly adapted to the interface of the machine.

Software/Control

Sinumerik 828D - incl. ShopTurn

High performance CNC control for ultimate accuracy and machining speed. SINUMERIK 828D and SINAMICS drive and motors are perfectly tailored for state of the art turning machines. Powerful CNC-functions combined with a unique 80bit NANOFP Accuracy (80 bit floating point accuracy from the position control to the internal encoder resolution) enable highest work-piece accuracy at a minimum of machining time. With a flexible CNC programming language and the state of the art ShopTurn machining step programming, single parts as well as large batch series can be programmed and machined with maximum effectiveness. Due to powerful kinematic transformations and a large set of technological cycles, SINUMERIK 828D also meets the demands of high sophisticated machine applications with driven tools and sub-spindle. Source picture and text: Siemens

![[Translate to en:] [Translate to en:]](/fileadmin/user_upload/_Group/pics_products/Steuerungen/Fanuc/fanuc_0i_TF.jpg)

Fanuc 0i TF

- Excellent value for money

- High-speed and nano-smoothing machining

- Fine surface technology combined with shortest cycle times

- Benchmark in terms of productivity / availability

- User-friendly MANUAL GUIDE i and 3-D Simulation

- Completely compatible with older Fanuc CNCs

- Same Operation, Programming and Maintenance as FANUC Series 3xi-B (seamless CNC)

- More than 25 years spare parts availability