This is how automation works

WHERE THE WORLD AUTOMATICALLY ROTATES AROUND A DISK

Modern production companies rely on machines that work with a small number of manual work steps and with a minimum of human monitoring. Automation is a term for the optimal combination of high tech and efficiency. Thanks to an innovative solution from EMCO, the automation of grinding wheel production at TYROLIT has been expanded to a level which is technically remarkable.

TYROLIT has relied on Emco as a production partner for many years. The high level of cooperation and mutual trust was also crucial in taking another big step towards the modernisation of production.

The task:

Fully automate an established EMCO machine concept.

The result:

New possibilities and more output than calculated.

Efficiency meets resource conservation

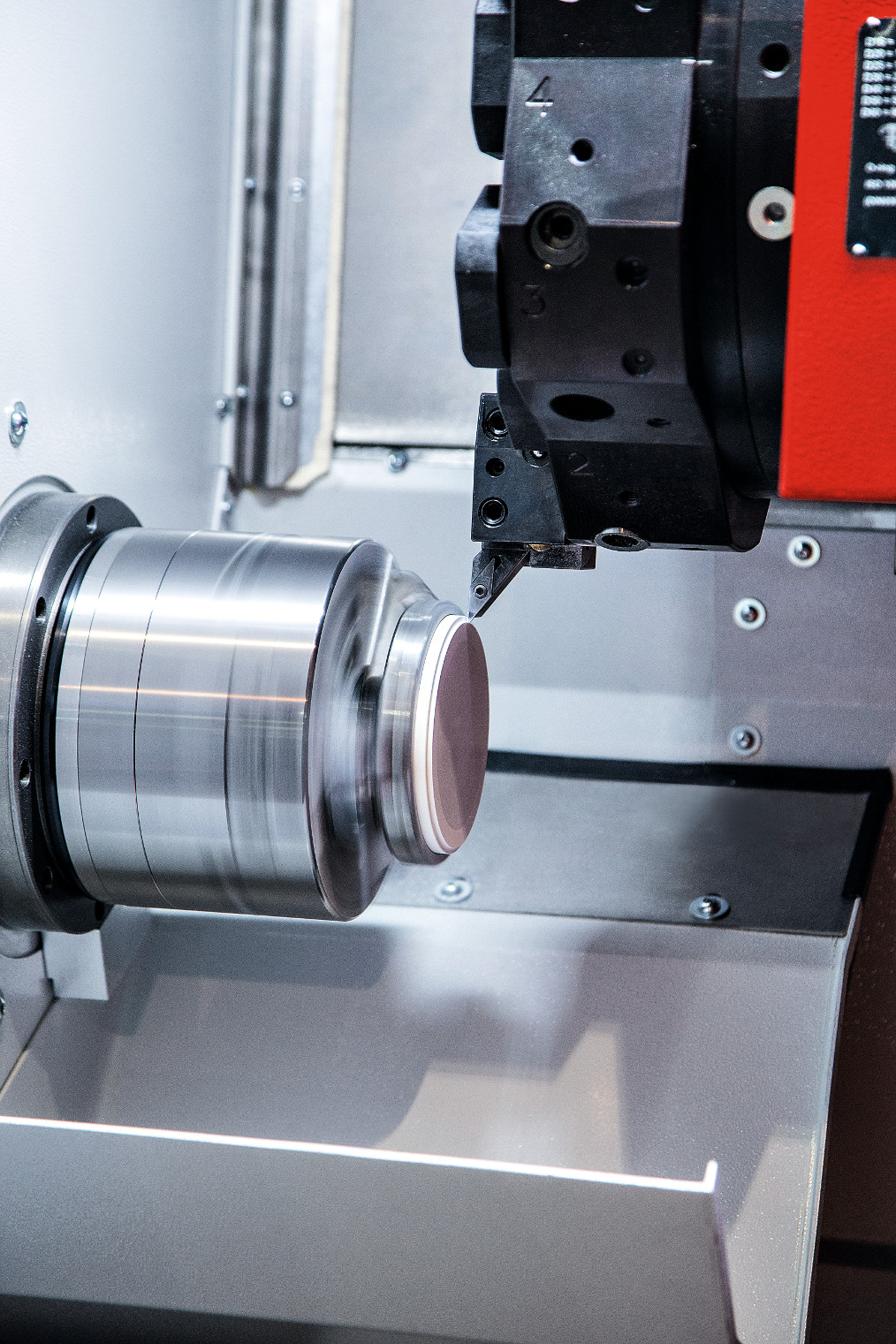

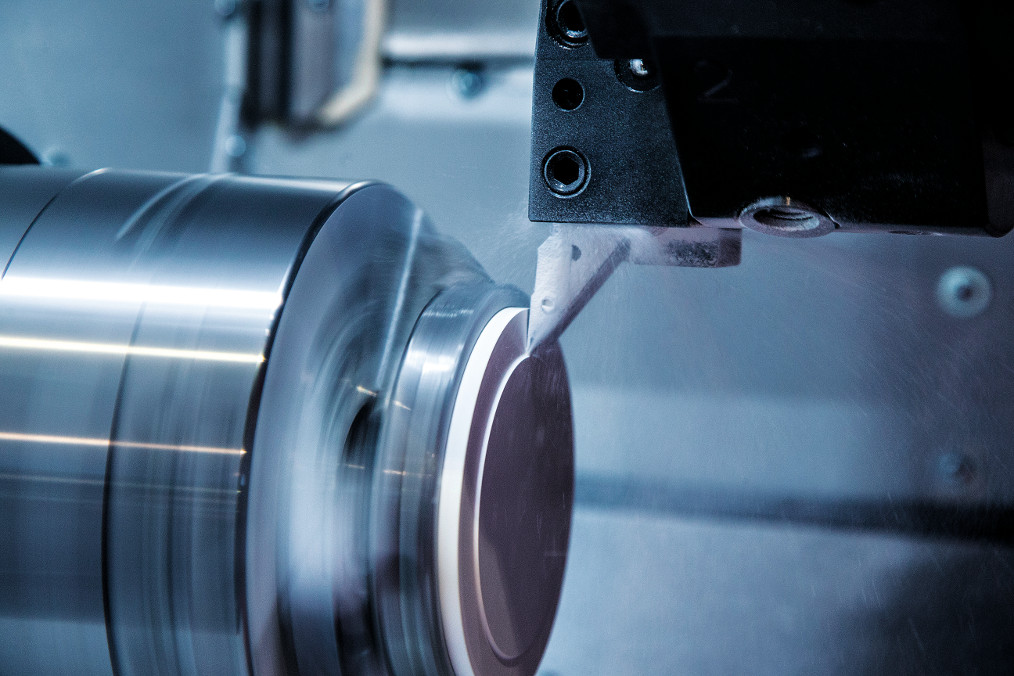

The task at hand: the dressing or over-turning of ceramic bonded grinding wheels. This was a challenge on a whole range of levels. The focus was not just on a smooth and efficient production process. Innovative automation solutions and a highly sophisticated dust protection system were also required. In addition, all devices had to be able to communicate with each other to ensure that the complex chain of operations could function without errors.

Machine networking as a success factor

After a thorough and detailed planning process, a Hyperturn 45 with robot support, integrated measuring process and special dust protection concept was built for production. The goal of low-staff or unstaffed production was not only achieved, but even exceeded. Where loading, surveying, correction, labelling and unloading were previously done by hand, now interconnected machines are in place, which do their job thanks to optimal coordination, to the great pleasure of TYROLIT’s managers

A great deal of knowledge and pleasant experiences

The extensive know-how of EMCO in the project-relevant areas was evident right from the off. This encouraged the customer to put the responsibility for an important step forward in the production process in reliable hands. Fast communication channels, quick and pragmatic solutions and good all-round customer service were additional advantages that played an important role in TYROLIT choosing EMCO.

Again, this was a very challenging task because the optimal coordination of various automation components was new territory. But with close cooperation and with a lot of know-how, the end result was once again successful. In the end, it was even better than first planned:

Johannes Jäger, Maintenance, TYROLIT

When people and machines communicate constructively with each other, good things happen. For example, an automation solution in which all parties involved in the planning have an eye on all the details and possibilities. Dust protection, robots and innovative connections between machines result in an all-round package that guarantees more quality with a lower use of resources. This is also due to the great experience of EMCO, a history of good cooperation and the well-organised coordination process.

Dust cover as a resource saver

The dust cover installed in the Hyperturn 45 was jointly developed by EMCO and TYROLIT. It is highly innovative and designed and built in such a way that the defined production processes are optimally supported by the machine sealing. The goal is to conserve resources by extracting potentially abrasive dust particles. The guides are protected, maintenance work is reduced and the overall lifetime is increased. In addition, a dust conveyor belt, a highly efficient extraction and air purge on the turret and spindle prevent particles from wearing on the machine.

Robots as reliable processors

At the beginning of production, the robot scans the barcode of the blank to be processed and the appropriate programs are loaded. Then the parts are automatically fed and processed. The finished parts are measured and adjusted. The robot also performs the shelving at the end of the process. The robot hardware is supplied by ABB and integrated into the overall concept with EMCO expertise.