Emco Vertical VT 160

EQUIPMENT

Technische Daten

Arbeitsbereich

| Verfahrweg in X/Y/Z | 620 / +/-65 / 310 mm |

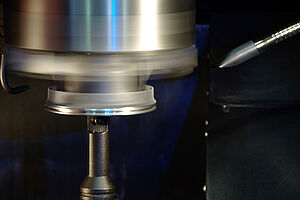

| Max. Drehdurchmesser | 160 mm |

| Umlaufdurchmesser über Bett | 160 mm |

| Eilganggeschwindigkeit X/Y/Z | 60/15/30 m/min |

| Max. Vorschubkraft in X/Y/Z | 6000/6000/6000 N |

Hauptspindel

| Max. Drehzahl | 7000 U/min (Motorspindel) |

| Spindelanschluss | A 2-5 |

| Max. Antriebsleistung | 21 kW (motor spindle) |

| Max. Drehmoment | 150 Nm |

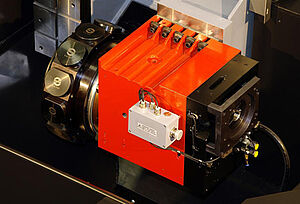

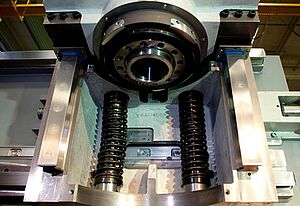

Werkzeugrevolver

| VDI Größe | 30 |

| Anzahl der Werkzeugpositionen | 12 |

| Angetriebene Werkzeuge | 12 |

| Max. Drehzahl | 5000 rpm |

| Max. Antriebsleistung | 6,7 kW |

| Max. Drehmoment | 25 Nm |

Highlights

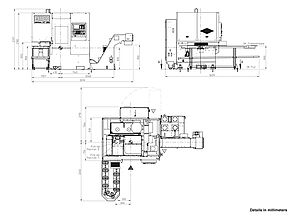

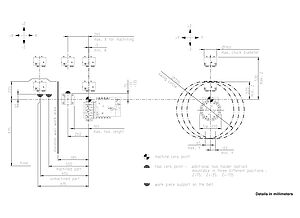

Aufstellplan/Arbeitsraum

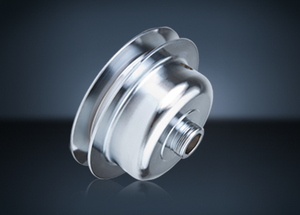

Werkstücke

Examples of use

Versionen

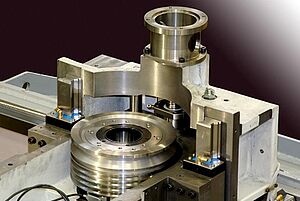

EMCO VERTICAL VT 160 MY (ISM)

Machine with driven tools, Y axis and integrated spindle motorOptionen/Zubehör

Hochdruck-Kühlmittelpumpe

Kühlmitteldurchführung durch die Spindel über Deublin-Drehdurchführung bis maximal 70 bar. Das Kühlmittel wird direkt durch die Spindel auf die Schneide geführt.Electronic handwheel - CNC

For moving the machine’s axes manually to set zero point and tool offsets.High pressure coolant pump LM 600

Via a rotary coupling the tools are provided with a coolant (coolant through spindle system) with a 20 or 70 bar high pressure pump.Steuerung/Software

Sinumerik 828D - incl. ShopTurn

High performance CNC control for ultimate accuracy and machining speed. SINUMERIK 828D and SINAMICS drive and motors are perfectly tailored for state of the art turning machines. Powerful CNC-functions combined with a unique 80bit NANOFP Accuracy (80 bit floating point accuracy from the position control to the internal encoder resolution) enable highest work-piece accuracy at a minimum of machining time. With a flexible CNC programming language and the state of the art ShopTurn machining step programming, single parts as well as large batch series can be programmed and machined with maximum effectiveness. Due to powerful kinematic transformations and a large set of technological cycles, SINUMERIK 828D also meets the demands of high sophisticated machine applications with driven tools and sub-spindle. Source picture and text: Siemens