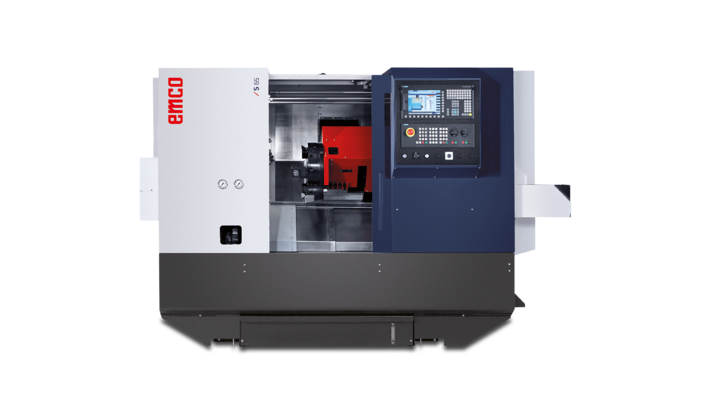

CNC-Lathe S65

EQUIPMENT

Technische Daten

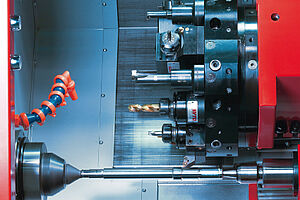

Arbeitsbereich

| Verfahrweg in X/Y/Z | 210/ - / 610 mm |

| Max. Stangendurchlass | ø 65 mm |

| Max. Drehdurchmesser | ø 310 mm |

| Umlaufdurchmesser über Bett | ø 540 mm |

| Spitzenweite | Spindle Nose-Center 680 mm |

Hauptspindel

| Max. Drehzahl | 4200 rpm |

| Max. Antriebsleistung | 18 kW |

| Max. Drehmoment | 192 Nm |

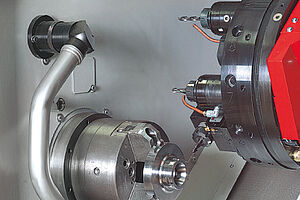

Werkzeugrevolver

| Anzahl der Werkzeugpositionen | 12 |

| Angetriebene Werkzeuge | 12 |

| Max. Drehzahl | 5000 rpm |

| Max. Antriebsleistung | 5 kW |

| Max. Drehmoment | 20 Nm |

Abmessungen

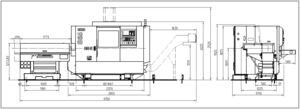

| Dimensionen (LxBxH) | 2855 x 1770 x 1880 mm |

| Maschinengewicht | 4300 kg |

Highlights

Aufstellplan/Arbeitsraum

Werkstücke

Examples of use

Steuerung/Software

Sinumerik 828D - incl. ShopTurn

High performance CNC control for ultimate accuracy and machining speed. SINUMERIK 828D and SINAMICS drive and motors are perfectly tailored for state of the art turning machines. Powerful CNC-functions combined with a unique 80bit NANOFP Accuracy (80 bit floating point accuracy from the position control to the internal encoder resolution) enable highest work-piece accuracy at a minimum of machining time. With a flexible CNC programming language and the state of the art ShopTurn machining step programming, single parts as well as large batch series can be programmed and machined with maximum effectiveness. Due to powerful kinematic transformations and a large set of technological cycles, SINUMERIK 828D also meets the demands of high sophisticated machine applications with driven tools and sub-spindle. Source picture and text: Siemens

![[Translate to en:] [Translate to en:]](/fileadmin/user_upload/_Group/pics_products/Steuerungen/Fanuc/fanuc_0i_TF.jpg)

Fanuc 0i TF

- Excellent value for money

- High-speed and nano-smoothing machining

- Fine surface technology combined with shortest cycle times

- Benchmark in terms of productivity / availability

- User-friendly MANUAL GUIDE i and 3-D Simulation

- Completely compatible with older Fanuc CNCs

- Same Operation, Programming and Maintenance as FANUC Series 3xi-B (seamless CNC)

- More than 25 years spare parts availability