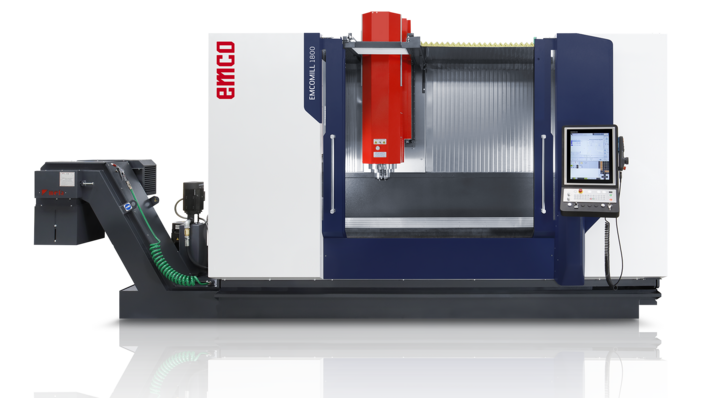

Emcomill 1800

EQUIPMENT

Technische Daten

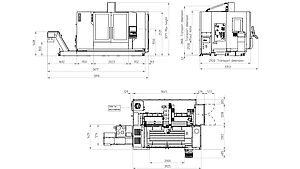

Arbeitsbereich

| Verfahrweg in X/Y/Z | 1800/610/500 mm |

| Abstand Spindelnase Tisch | 175/675 mm (mechanical spindle) / 150/650 mm (motor spindle) |

| Anzahl der Achsen (Basisversion) | 3 (4 opt.) |

| Eilganggeschwindigkeit X/Y/Z | 30 m/min |

| Arbeitsvorschub X/Y/Z | 15 m/min |

| Aufspannfläche | 2000x650 mm |

| Max. Tischbelastung | 2000 kg |

Motorspindel

| Spindel-Drehzahl | 50-15000 rpm |

| Antriebsleistung | 20 kW |

| Max. Drehmoment | 100 Nm |

Mechanische Spindel

| Max. Drehzahl | 50-12000 rpm |

| Antriebsleistung (S6) | 15 kW |

| Max. Drehmoment (S6) | 100 Nm |

Werkzeugwechsel

| Anzahl der Werkzeugplätze | 30 (40/60) |

| Werkzeugwechselzeit (WZ/WZ) | 2 sec. |

| Max. Werkzeugdurchmesser | 75 mm |

| Max. Werkzeuglänge | 250 mm |

Abmessungen

| Dimensionen (LxBxH) | 3360x4420x3070 mm |

| Maschinengewicht | 14000 kg |

Highlights

High performance spindles

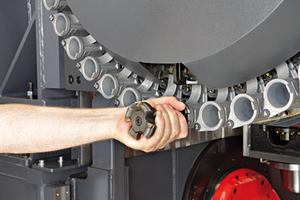

You can choose between two variants for different areas of application: 12,000 rpm (direct drive) or 15,000 rpm (motor spindle).TOOL MAGAZINE

The tool magazine has 30 stations (40/60 as option). The tool management with random tool selection uses a double-gripper that allows to make a pre-search of the tool during the machining cycle. Alternatively it is possible to utilise the tool magazine with a fixed place for big-dimensioned tools, leaving the two adjacent stations free.BALL SCREWS

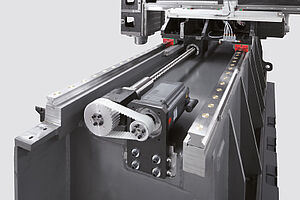

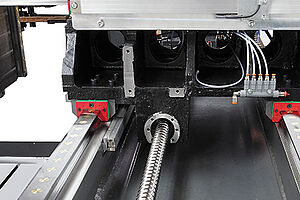

Grease-lubricated (central) ball screws and linear roller guides (45 mm in the X- and Y-axes; 35 mm in the Z-axis) offer high resistance against mechanical stress and a high, zero-vibration traverse speed. On the picture, machine equipped with linear scales (option).DESIGN

The new EMCOMILL series is designed as a moving column milling machine. The machine bed is made in welded steel, optimised by FEM analysis. The X-, Y- and Z-slides are made in cast iron.Aufstellplan/Arbeitsraum

Optionen/Zubehör

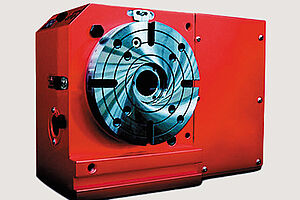

Rotary table

As 4th axis a rotary table with 200 mm diameter can be mounted on customer's request. The rotary table travels CNC controlled and can interpolate with any linear axis (X, Y, Z). For maximum precision in the parts production.SIDE TOOL MAGAZINE DOOR

The side tool magazine door allows fast loading and unloading, as well as control and cleaning of the tools.MEASURING SYSTEMS

Both the measurement of the tool to reduce the set-up time during tool change as well as the measurement of the workpiece in order to check dimensions or to determine zero points, is optionally possible within the machine by means of a radio or a laser bridge.GLASS SCALES IN X, Y, Z AXES

Glass scales are used for measuring linear position, eliminating thermal deviations and increasing machine accuracy. The pressurisation prevents the scales‘ contamination.Steuerung/Software

Sinumerik 828D - incl. ShopMill

SINUMERIK 828D: High performance CNC control for ultimate accuracy and machining speed SINUMERIK 828D and SINAMICS drive and motors are perfectly tailored for state of the art milling machines. Powerful CNC-functions combined with a unique 80bit NANOFP Accuracy (80 bit floating point accuracy from the position control to the internal encoder resolution) enable highest work-piece accuracy at a minimum of machining time. With a flexible CNC programming language and the state of the art ShopMill machining step programming, single parts as well as large batch series can be programmed and machined with maximum effectiveness. Due to Advanced Surface, an innovative method of velocity and path control, SINUMERIK 828D also meets the demands of high sophisticated mold & die applications. Source picture and text: Siemens

Heidenhain TNC 620

The latest control offers milling operations, a 19'' TFT colour display and 3D-reproduction and programming graphics.

It is particularly suitable for Mill, HSC- and 5 axis operations at machines up to 6 axes.